In the realm of flood remediation and structural drying, a crucial dehumidification step emerges to combat water damage effectively, especially in wet materials with extra moisture. This method, rooted in historical practices, aims to restore buildings post-water infiltration swiftly. By harnessing advanced techniques and tools, structural drying expedites the drying process, preventing mold growth and structural deterioration. Understanding the significance of prompt action in such scenarios is paramount for mitigation and mitigating long-term consequences. Through strategic placement of equipment and thorough monitoring, this procedure ensures a comprehensive restoration approach. Stay tuned as we delve deeper into the intricacies of structural drying and mitigation, and unveil its pivotal role in safeguarding properties against water-related perils.

Key Takeaways

-

Act promptly: Start the drying process as soon as possible to prevent further damage to your property.

-

Utilize professional services: Consider hiring experts in structural drying to ensure thorough and effective restoration.

-

Monitor progress: Keep track of the drying phases and adjust techniques if necessary for optimal results.

-

Invest in quality equipment: Use reliable tools and technology to expedite the drying process and minimize potential risks.

-

Prioritize mold prevention: Structural drying not only restores but also helps prevent mold growth, safeguarding your property and health.

-

Choose the right method: Assess different drying techniques to determine the most efficient and suitable approach for your specific situation.

Understanding Structural Drying

Role

Structural drying is the process of removing moisture from building materials after water damage. It involves utilizing specialized equipment for mitigation to extract water and restore the affected structure.

Structural drying plays a crucial role in preventing mold growth and structural damage. By swiftly removing moisture, a water damage restorer inhibits the growth of mold, which can lead to health issues and further deterioration of the building.

Significance

Timely structural drying, mitigation, is essential to prevent extensive demolition and costly repairs. When water infiltrates a structure, immediate mitigation action is necessary to minimize long-term damage. Failure to dry the structure promptly can result in warped floors, weakened foundations, compromised structural integrity, and the need for a water damage restorer for mitigation.

Effective communication about the structural drying process is key in reducing client stress. Providing clear explanations about the steps involved, expected timelines, and potential outcomes helps clients understand the restoration process better.

Communication

Clear communication between restoration professionals, clients, and mitigation is vital for a successful structural drying process. By keeping clients informed about each stage of drying, including the equipment used and progress made, trust is built, and anxiety is reduced.

-

Pros of Effective Communication:

-

Builds trust between clients and restoration professionals.

-

Reduces client stress and uncertainty.

-

Ensures clients are aware of the progress and expected outcomes.

-

-

Cons of Ineffective Communication:

-

Increases client anxiety and frustration.

-

Leads to misunderstandings about the drying process.

-

Phases of the Drying Process

Key Principles

Structural drying involves four key principles: water extraction, air movement, dehumidification, and temperature control. Water extraction is the initial step in mitigation to remove excess water from the affected area.

Air movement plays a crucial role in promoting evaporation by circulating dry air across wet surfaces. This process accelerates drying and helps prevent mold growth, ensuring a successful restoration.

Dehumidification is essential to reduce moisture levels in the air, extracting excess humidity to speed up the drying process. By removing moisture from the air, dehumidifiers contribute significantly to drying efficiency.

Maintaining consistent temperature is vital during structural drying. Temperature control aids in enhancing evaporation rates and overall drying effectiveness. It ensures that the environment remains conducive to drying out the materials effectively.

Importance of Air Movement

Effective air movement is critical in structural drying as it facilitates evaporation by introducing dry air into the affected area. This circulation helps to prevent mold growth by reducing moisture levels and promoting rapid drying.

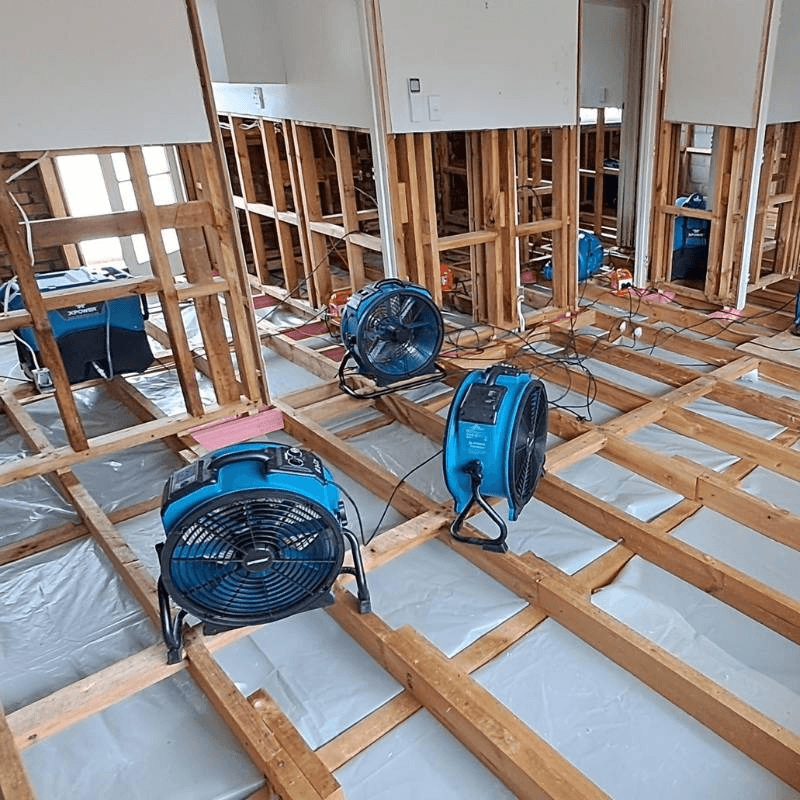

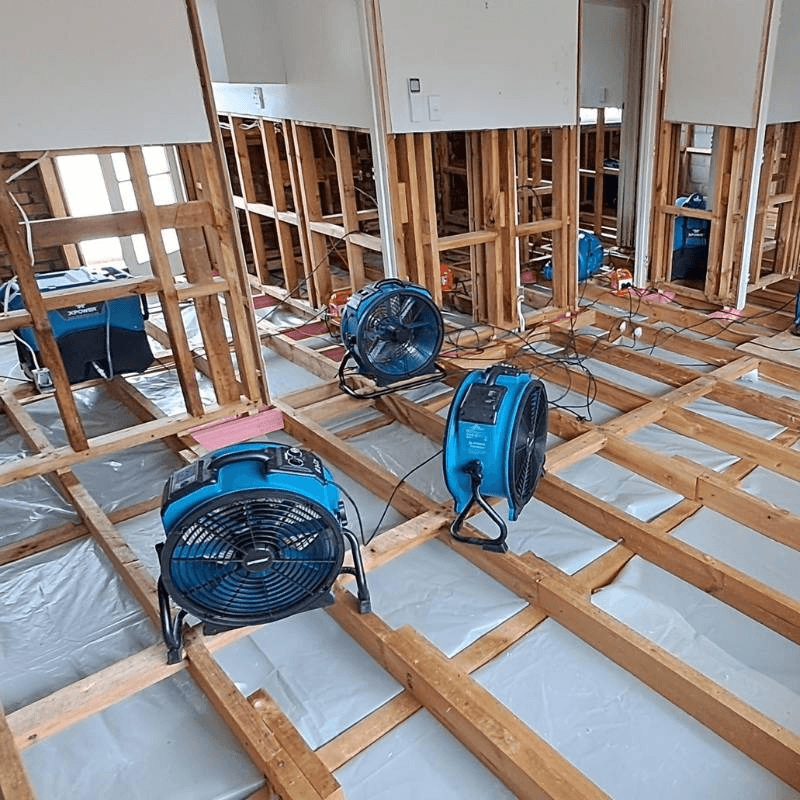

By utilizing fans and other equipment, professionals can ensure that moist air is replaced with drier air, expediting the drying process. Proper air movement also aids in maintaining a balanced environment conducive to efficient drying without causing secondary damages like mold or mildew growth.

Consistent Temperature Maintenance

Consistent temperature maintenance is key to achieving optimal results during structural drying. By controlling the temperature within the drying environment, professionals can enhance the efficiency of the overall drying process.

Maintaining a stable temperature helps to accelerate evaporation rates, ensuring that materials dry thoroughly and quickly. Consistent temperature control aids in preventing fluctuations that could impede the progress of structural drying efforts.

Essential Equipment for Drying

Types of Equipment

-

Dehumidifiers: These machines remove extra moisture from the air, reducing humidity levels and accelerating the drying process.

-

Air Movers: By creating airflow over wet materials, air movers help in evaporating the moisture quickly.

Functions of Equipment

Dehumidifiers work by pulling in moist air, extracting the moisture, and then releasing dry air back into the environment. On the other hand, air movers enhance evaporation by circulating air around damp materials, expediting the drying time.

Impact on Drying Process

Proper selection of drying elements is crucial for efficient structural drying. Using the right equipment ensures that excess moisture is effectively removed, preventing issues like mold growth and structural damage.

When dehumidifiers and air movers are strategically placed based on moisture detection readings from moisture meters, they create an optimal environment for drying. This approach not only speeds up the process but also ensures thorough removal of excessive dampness.

Technology in Structural Drying

Moisture Meters

Moisture meters play a crucial role in applied structural drying, enabling professionals to accurately measure moisture levels in structural materials. By utilizing these devices, technicians can identify areas with high moisture content, guiding them in the drying process effectively.

Moisture meters come in various types, such as pin-type and pinless meters. Pin-type meters penetrate the material’s surface to provide moisture readings, while pinless meters use electromagnetic signals to detect moisture without damaging the material. This diversity allows for flexibility in assessing different types of structure materials.

Thermal Imaging

Thermal imaging technology has revolutionized structural drying by offering a non-invasive method to detect moisture within building materials. These cameras capture infrared radiation emitted by objects to create detailed images showing variations in temperature, indicating areas of moisture accumulation.

By using thermal imaging during the drying process, technicians can quickly identify hidden pockets of moisture behind walls or ceilings that may not be visible to the naked eye. This advanced technology enhances the efficiency of drying procedures, ensuring thorough moisture removal from structure materials.

Automation in Drying Processes

Automation plays a significant role in streamlining applied structural drying, leading to improved efficiency and reduced labor costs. Automated systems can monitor and control various aspects of the drying process, such as humidity levels, airflow, and temperature, ensuring optimal conditions for moisture removal.

One key benefit of automation is the ability to adjust drying parameters remotely, allowing technicians to respond promptly to changing conditions without being physically present at the site. This real-time monitoring capability enhances the overall effectiveness of structural drying, resulting in faster restoration times and minimized damage to structure materials.

Alternative Drying Techniques

Aggressive Drying vs. Traditional Methods

Aggressive drying techniques involve utilizing commercial drying equipment that operates at higher temperatures and airflow rates compared to traditional methods. These methods aim to expedite the water remediation process by rapidly removing moisture from affected areas.

In contrast, traditional drying approaches rely on natural ventilation and dehumidification systems to gradually dry out the structure. While these methods are effective in many cases, they may not be suitable for situations requiring a faster turnaround time.

Scenarios Requiring Disruptive Drying

Additional building materials like concrete or hardwood floors may necessitate aggressive drying techniques due to their high moisture retention properties. In scenarios where mold growth is a concern, disruptive drying becomes essential to prevent further damage and contamination.

Implementing disruptive drying in such scenarios can help mitigate potential structural issues and health hazards associated with prolonged exposure to excess moisture.

Benefits and Drawbacks of Alternative Drying Techniques

Pros:

-

Faster Drying: Aggressive drying methods can significantly reduce the water remediation process timeline, allowing for quicker restoration of the affected area.

-

Prevention of Secondary Damage: By swiftly removing moisture, disruptive drying helps prevent mold growth and structural deterioration.

Cons:

-

Potential Damage: The intense heat and airflow generated by aggressive drying equipment may cause damage to sensitive materials or contents within the space.

-

Higher Energy Consumption: Aggressive drying techniques often require more energy to operate efficiently, leading to increased utility costs.

Advantages of Structural Drying

Cost-Effectiveness

Structural drying offers significant cost savings compared to extensive repairs. By swiftly addressing water damage, property owners can avoid the need for costly renovations and replacements. This method focuses on restoring affected areas efficiently, preventing the escalation of damages that would require more extensive and expensive solutions.

Speed of Restoration

Property owners benefit from the rapid restoration process facilitated by structural drying. Unlike traditional methods that may take weeks or even months to complete, this technique minimizes downtime. Quick action not only reduces inconvenience for occupants but also prevents secondary issues such as mold growth, which can further prolong the restoration process.

Preservation of Structural Integrity

One of the key advantages of structural drying is its ability to preserve building materials and maintain structural integrity. By promptly removing excess moisture from affected areas, this method prevents structural components from weakening or deteriorating over time. Preserving the integrity of the building ensures its longevity and minimizes the risk of structural failures in the future.

Impact on Property Restoration

Minimizing Secondary Damage

Structural drying plays a crucial role in minimizing secondary damage, particularly mold growth, after water damage. By swiftly removing excess moisture from the property, restoration professionals can prevent mold spores from thriving in damp environments. This proactive approach not only safeguards the structural integrity of the building but also safeguards indoor air quality.

Effective drying procedures significantly reduce the likelihood of extensive demolition due to structural damage caused by prolonged exposure to water. By promptly initiating the drying process, restoration experts can salvage materials that would otherwise require costly repairs or replacements. This not only accelerates the restoration process but also minimizes disruptive renovations that can inconvenience occupants.

Professional Drying Services

Engaging professional drying services is paramount in ensuring comprehensive property restoration post-water damage incidents. These experts possess the technical expertise and advanced equipment necessary to conduct thorough water damage mitigation through efficient drying techniques. Their specialized knowledge allows them to identify hidden pockets of moisture and address them before they escalate into more significant issues.

By entrusting the property to skilled water damage restorers, property owners can rest assured that every corner of the structure undergoes meticulous drying, leaving no room for potential water-related problems to resurface. Moreover, these professionals adhere to industry best practices and safety standards, guaranteeing a thorough and effective restoration process that prioritizes both the property’s integrity and the occupants’ well-being.

Importance of Timely Drying

Timely structural drying is imperative in mitigating water damage losses and expediting the restoration timeline. Swiftly extracting water and implementing efficient drying methods significantly reduce the overall cost of repairs, as it prevents further deterioration of materials and structures. Rapid drying helps prevent the onset of microbial growth, safeguarding occupants from potential health hazards associated with mold and mildew.

Property owners who prioritize prompt structural drying demonstrate a commitment to preserving their investments and ensuring a safe living or working environment for occupants. By recognizing the critical role of drying in the aftermath of water damage, individuals can proactively address issues before they escalate, ultimately leading to a quicker and more successful property restoration process.

Mold Prevention Benefits

Effective Prevention

Structural drying plays a crucial role in reducing the risk of mold development within properties. By swiftly removing excess moisture from affected areas, structural drying inhibits the conditions necessary for mold growth. This method targets the root cause of mold proliferation, preventing further damage to the property.

Health Benefits

Preventing mold through efficient structural drying not only safeguards the property but also ensures long-term health benefits for occupants. Exposure to mold can trigger respiratory issues, allergies, and other health concerns. By addressing moisture promptly, property owners can create a healthier indoor environment, promoting overall well-being.

Timely Intervention

Timely intervention in mold prevention strategies is paramount to mitigating risks associated with mold and asbestos exposure. Mold growth can occur rapidly in damp environments, leading to extensive damage and potential health hazards. Implementing structural drying as part of a comprehensive mold prevention plan allows for early detection and resolution of moisture issues.

Efficiency of Drying Methods

Disruptive Drying

Disruptive drying techniques involve removing water rapidly from the affected area to prevent further damage. This method utilizes high-velocity air movers to create turbulence and accelerate moisture evaporation.

Dehumidification Method

The dehumidification method focuses on reducing humidity levels in the air, aiding in moisture retention control. By extracting excess moisture, this approach effectively dries out structures and contents.

Aggressive Drying

Aggressive drying strategies involve intense airflow and dehumidification to expedite the drying process. This method is crucial for mitigating extensive water damage and preventing mold growth.

Importance of Airflow

Proper airflow plays a vital role in enhancing drying efficiency by facilitating moisture evaporation. Strategic placement of air movers and dehumidifiers optimizes airflow patterns for thorough drying.

Selecting the Right Method

Choosing the appropriate drying method is essential to ensure efficient water extraction and property restoration. Factors such as the extent of water damage, building materials, and environmental conditions influence the selection process.

Cost and Time Considerations

Efficiency in drying methods directly impacts the overall cost and time required for property restoration. Swift and effective drying reduces secondary damages, minimizing expenses and shortening the restoration timeline.

Tailoring Solutions to Specific Needs

Each water damage scenario requires a tailored approach to drying methods based on the unique circumstances involved. Understanding the intricacies of disruptive drying, dehumidification, and aggressive drying is crucial for successful restoration outcomes.

Summary

In understanding structural drying, you’ve learned about its phases, essential equipment, technology, and alternative techniques. The advantages are clear, impacting property restoration positively while preventing mold growth efficiently. Embracing these methods ensures a quicker and more effective recovery process.

For optimal results in property restoration, apply the insights gained here to make informed decisions on structural drying. Your proactive approach will not only save time and costs but also safeguard your property from potential long-term damage. Implement these strategies confidently to enhance your property’s resilience and longevity.

Frequently Asked Questions

What is structural drying?

Structural drying is the process of removing moisture from building materials after water damage to prevent further issues like mold growth and structural damage.

Why is understanding structural drying important?

Understanding structural drying helps in efficiently restoring properties post-water damage, ensuring safety, preventing mold growth, and preserving the structural integrity of buildings.

What equipment is essential for structural drying?

Essential equipment for structural drying includes dehumidifiers, air movers, moisture meters, and thermal imaging cameras to effectively dry out affected areas and monitor progress.

How does technology play a role in structural drying?

Technology enhances structural drying processes by providing accurate moisture readings, improving efficiency, and enabling precise monitoring to ensure thorough drying and prevent secondary damage.

What are the advantages of utilizing structural drying methods?

Utilizing structural drying methods speeds up the restoration process, minimizes property damage, reduces health risks associated with mold growth, and helps in preserving the value of the property.